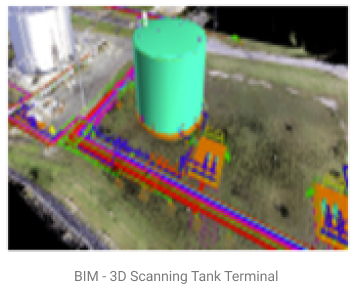

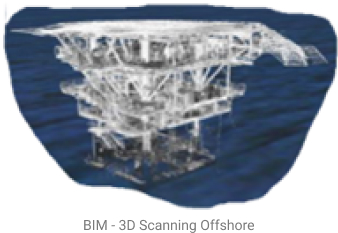

Damgaard uses 3D laser scanning tools to capture over a million data points per second to accurately detail the geometry and existing condition of your facility. These scans produce exact replications of your facility on the inside as well as the outside so we can use the data to implement any kind of expansion or modification.

3D scanning has many advantages for today’s industrial plant projects, but also for future projects. Scans can be used repeatedly for improvements to your facility. Working with Damgaard, your scans are a confidential asset we can access for all your future projects. Accurate scans can help shave as much as 2 months off the time frame projected to complete a project. There is no need to re-scan your facility or for costly site visits.

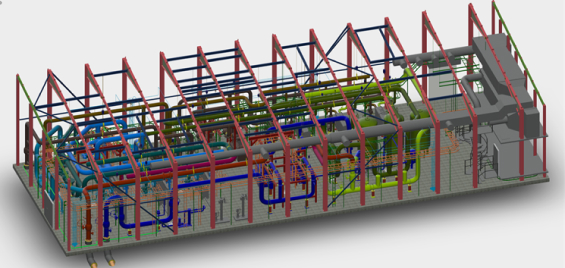

Once Damgaard’s scans are converted into 3D CAD plans with Revit and other Building Information Modeling (BIM) software, then we can evaluate alternative designs during the planning phase prior to construction. This technology will detect any clashes in proposed designs so your project will be built right the first time.

Building Information Modeling (BIM) thoroughly assesses the design and construction of all aspects of your facility including infrastructure, and utilities. Limited space has historically been a concern for most plants, but BIM modeling gives you peace of mind to be sure equipment will have the proper access points and clearance for easy maintainability.

Accurate full-color models and all relevant information can be shared simultaneously by designers, engineers, and project managers. When everyone is working towards a common goal from 100% accurate designs, the end result is higher levels of efficiency, projects completed on-schedule, and requiring less re-work.